Course Description

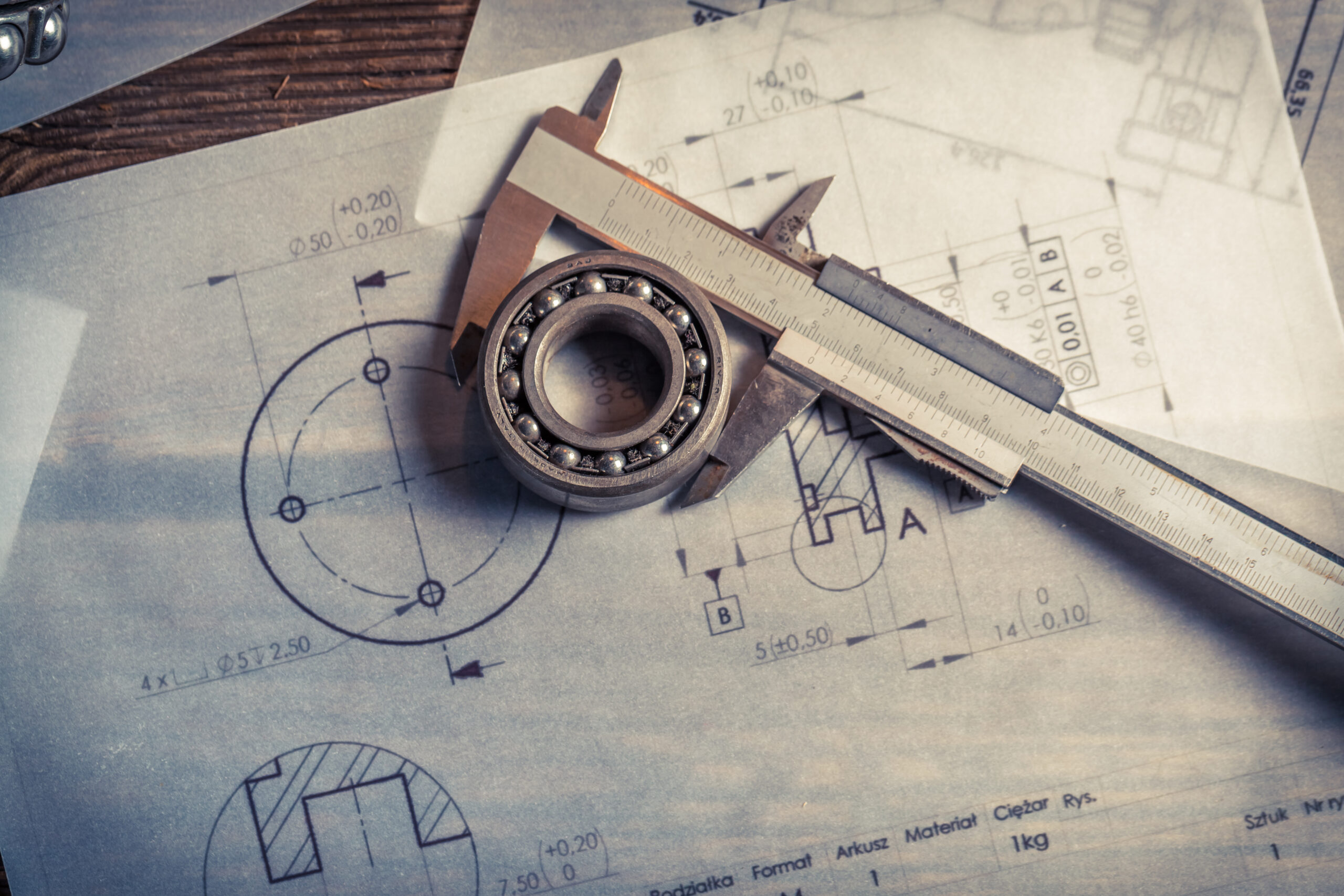

This 1-day Measurement Systems Analysis (MSA) course provides participants with the knowledge and skills to evaluate the accuracy, precision, and reliability of measurement systems used in manufacturing and service environments. MSA ensures that data used for decision-making is trustworthy, reducing the risk of costly mistakes caused by poor measurement quality.

Through interactive training, hands-on exercises, and practical examples, participants will learn how to conduct key MSA studies, including Gage Repeatability & Reproducibility (Gage R&R), bias, linearity, and stability assessments. The course emphasizes the financial benefits of MSA, such as reduced scrap and rework, improved product quality, better process control, and more effective problem-solving.

Course Objectives

Understand MSA Fundamentals:

– Define MSA and its role in quality assurance.

– Explain the importance of reliable measurement data.

Conduct Key MSA Studies:

– Perform Gage R&R (variable and attribute) studies.

– Assess measurement system bias, linearity, and stability.

Interpret and Use MSA Results:

– Analyze data to identify sources of measurement variation.

– Determine acceptability of measurement systems.

Link MSA to Financial Performance:

– Quantify savings from improved measurement reliability.

– Demonstrate ROI through reduced defects, scrap, and rework.

Integrate MSA into Continuous Improvement:

– Use MSA data to enhance SPC, problem-solving, and process capability efforts.

– Maintain ongoing measurement system verification.

Training Format

Day 1: Introduction to MSA principles, conducting Gage R&R and other MSA studies, interpreting results, linking MSA to financial performance, and developing an action plan for measurement system improvement.