Course Description

This 6-day Lean Six Sigma Green Belt course is aligned to ISO 18404, equips participants with the globally recognized skills to lead improvement projects that deliver significant, measurable financial gains.

ISO 18404 is the international benchmark for Lean Six Sigma competency, ensuring participants not only understand the tools and methods but can apply them effectively to deliver real business value. Completing this training provides independent proof of capability to reduce costs, eliminate waste, and improve processes in ways that directly boost the bottom line.

Through interactive workshops, data-driven exercises, and real-world case studies, participants will learn to identify and prioritize projects based on financial impact, reduce the Cost of Poor Quality (CoPQ), apply the DMAIC framework and Lean tools to eliminate waste and variation, and quantify savings often ranging from $50,000 to $250,000 per project.

Course Objectives

Master Lean Six Sigma Leadership Skills:

– Lead process improvement projects with measurable financial impact.

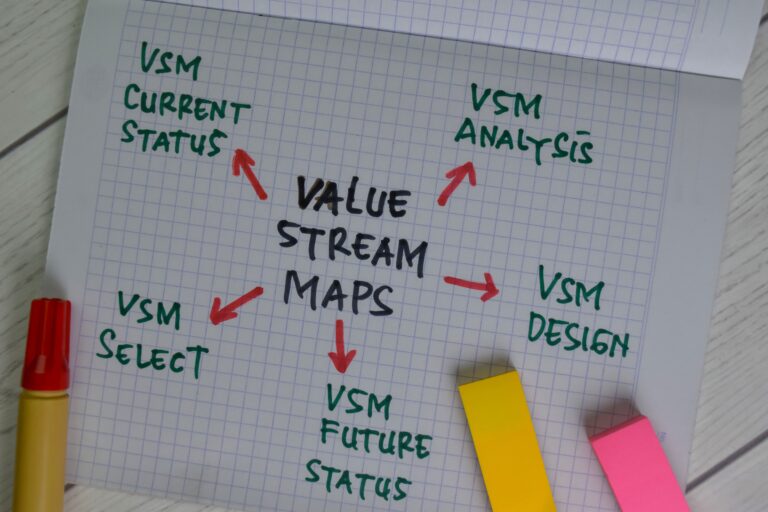

– Apply the DMAIC framework and Lean tools to drive efficiency.

Identify and Prioritize High-Impact Projects:

– Recognize and target processes with the highest waste or variation.

– Evaluate project potential based on ROI and business priorities.

Reduce Costs and Improve Quality:

– Minimize the Cost of Poor Quality (CoPQ) through data-driven analysis.

– Increase productivity and customer satisfaction.

Quantify and Communicate Financial Benefits:

– Translate improvement results into hard-dollar savings.

– Demonstrate ROI to stakeholders and leadership.

Sustain and Expand Improvements:

– Implement control plans and standardization methods.

– Build internal capability by mentoring Yellow Belt team members.

Training Format

Day 1: Introduction to Lean Six Sigma, ISO 18404 standards, and project selection.

Day 2: Define and Measure phases of DMAIC, data collection strategies, and measurement system analysis.

Day 3: Analyze phase, identifying root causes through statistical and Lean tools.

Day 4: Improve phase, solution generation, and piloting improvements.

Day 5: Control phase, sustaining gains, and advanced control tools.

Day 6: Project presentations, project assessment, and next steps for deployment.