Course Description

This immersive 2-day workshop introduces participants to the core principles of Lean through the use of the Lean Simulation Machine—a powerful, interactive tool that replicates real-world production and service processes.

Through multiple simulation rounds, participants will experience firsthand how waste impacts efficiency, quality, and customer satisfaction—and learn to apply Lean tools and techniques to transform process performance.

By practicing Lean principles in a simulated, risk-free environment, participants will see immediate cause-and-effect relationships between process changes and business results, including reduced cycle times, improved throughput, better quality, and lower costs.

The course emphasizes the financial benefits of Lean thinking, helping participants link process improvements to measurable savings and increased profitability in their own work areas.

Course Objectives

Understand Core Lean Principles:

– Define value from the customer’s perspective.

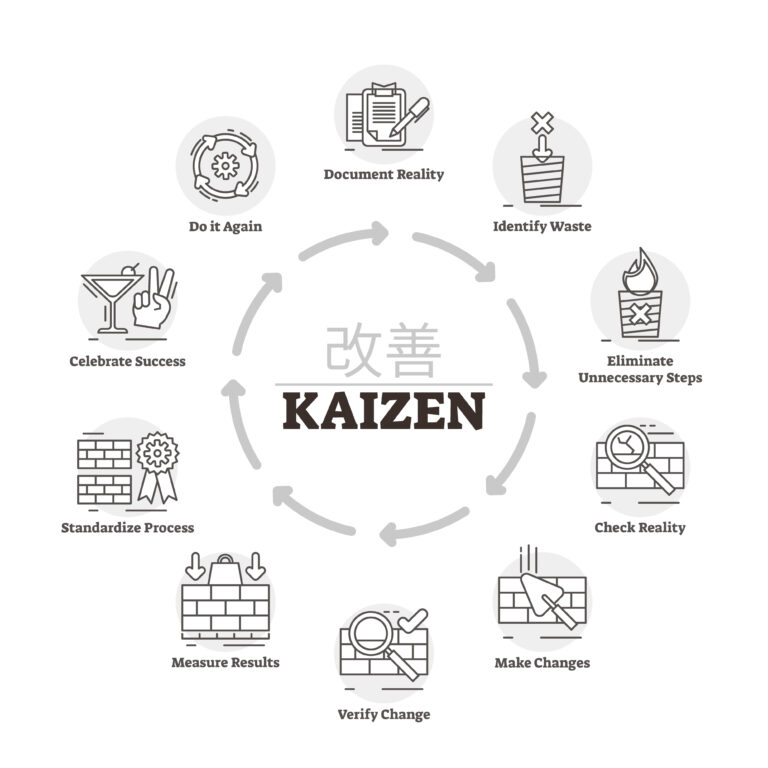

– Identify and eliminate the eight forms of waste.

– Explain flow, pull, and continuous improvement concepts.

Apply Lean Tools in Practice:

– Use value stream mapping to visualize and improve processes.

– Implement 5S, visual controls, and standard work to stabilize operations.

– Apply quick changeover (SMED) concepts to reduce downtime.

Analyze Process Performance:

– Measure and interpret lead time, cycle time, and throughput.

– Use simulation data to quantify the impact of improvements.

Recognize Financial Impact:

– Link Lean improvements to cost reduction, capacity gains, and ROI.

– Understand how waste elimination supports competitiveness and profitability.

Training Format Options

– Day 1: Introduction to Lean concepts, baseline simulation, waste identification, and initial improvements.

– Day 2: Advanced Lean tools, multiple simulation improvement rounds, and final performance review with financial impact analysis.