Course Description

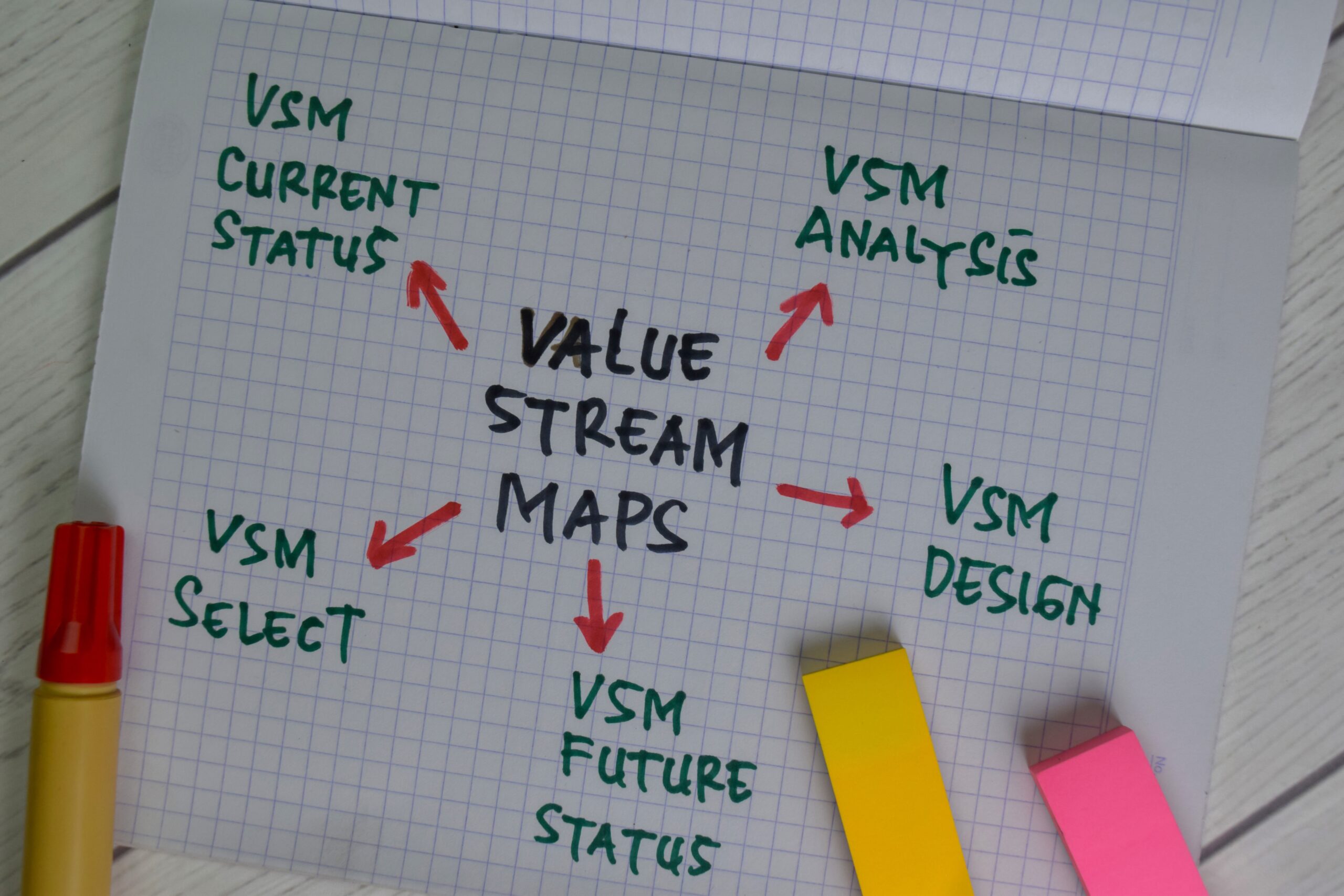

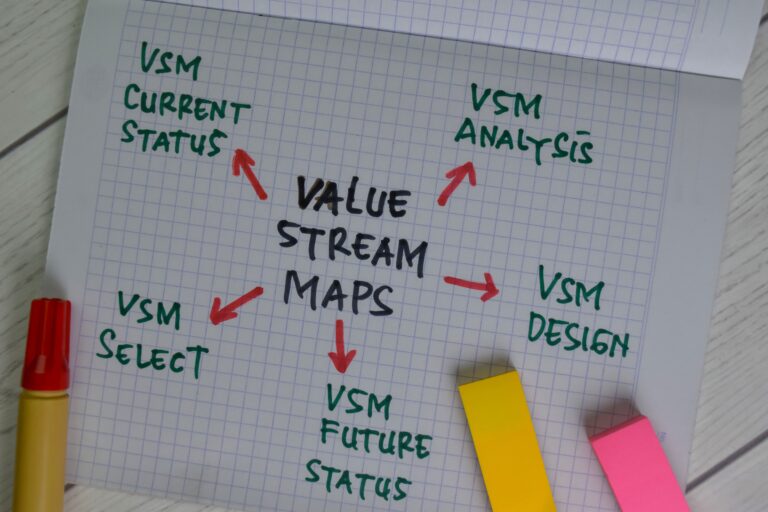

This intensive 3-day Value Stream Mapping (VSM) course equips participants with the skills to visually map, analyze, and redesign processes to improve efficiency, quality, and profitability. Using real-world case studies and interactive exercises, participants will learn how to identify value-added and non-value-added activities, eliminate waste, and design future-state processes that deliver measurable results.

VSM provides a powerful framework for linking operational improvements directly to financial performance. Participants will quantify the impact of process changes, from reduced lead times and inventory to increased capacity and lower costs. The course bridges the gap between Lean theory and business results, ensuring that improvement initiatives are both strategically aligned and financially justified.

Course Objectives

Understand the Purpose and Power of Value Stream Mapping:

– Explain the role of VSM in Lean transformation.

– Recognize how mapping supports strategic planning and ROI tracking.

Map Current-State Processes:

– Identify value-added and non-value-added steps.

– Measure process metrics such as lead time, cycle time, and inventory levels.

Analyze Process Flow and Waste:

– Identify the eight forms of waste.

– Highlight bottlenecks and constraints impacting cost and performance.

Design Future-State Maps:

– Apply Lean principles to create an improved process flow.

– Develop an actionable implementation plan tied to business priorities.

Quantify and Communicate Financial Impact:

– Translate process improvements into cost savings, capacity gains, and improved profitability.

– Build a financial case for leadership buy-in.

Training Format Options

– Day 1: Introduction to VSM concepts, Lean principles, and mapping techniques; create the current-state map.

– Day 2: Analyze the current-state map for waste and bottlenecks; identify improvement opportunities; begin future-state design.

– Day 3: Finalize the future-state map; develop an implementation plan; calculate and present the financial benefits of the new process.