Course Description

This focused Autonomous Maintenance (AM) course (1 or 2 days) equips operators and front-line teams with the skills and mindset to take ownership of basic equipment care, forming a key pillar of Total Productive Maintenance (TPM). Autonomous Maintenance empowers operators to perform routine maintenance tasks such as cleaning, inspection, and minor adjustments, preventing breakdowns and ensuring optimal machine performance.

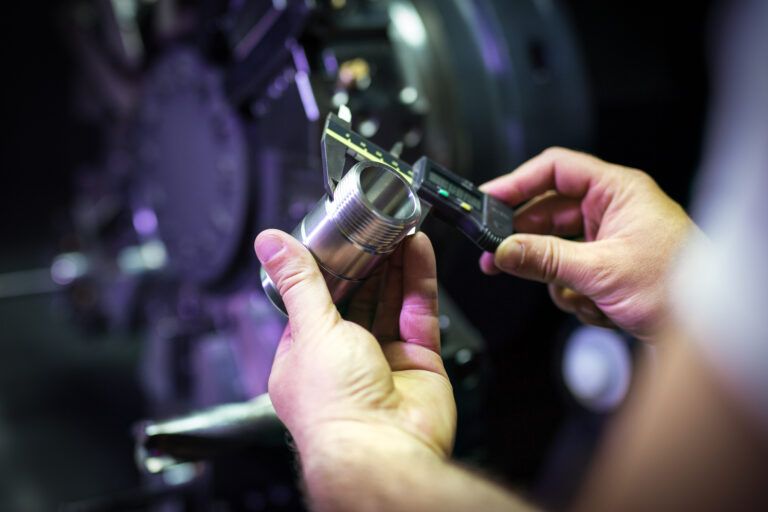

Through interactive workshops, hands-on exercises, and practical application on real or simulated equipment, participants will learn to detect early warning signs of equipment problems, maintain operating standards, and contribute to continuous improvement. The course emphasizes the financial benefits of AM, including reduced downtime, fewer maintenance interventions, lower repair costs, and increased equipment availability without additional capital investment.

Course Objectives

Understand Autonomous Maintenance Principles:

– Define AM and its role within Total Productive Maintenance.

– Recognize the benefits of operator-driven equipment care.

Perform Basic Equipment Care:

– Conduct cleaning, inspection, and lubrication routines.

– Identify and correct minor equipment abnormalities.

Prevent Equipment Failures:

– Detect early warning signs of wear and malfunction.

– Implement measures to prevent breakdowns and extend asset life.

Link AM to Financial Performance:

– Quantify cost savings from reduced downtime, lower repair expenses, and improved OEE.

– Demonstrate ROI from empowering operators in maintenance activities.

Sustain AM Practices:

– Standardize operator maintenance tasks.

– Develop visual controls and checklists for daily equipment care.

Training Options

– 1-Day: Introduction to AM principles, basic maintenance routines, and pilot implementation in a work area.

– 2-Day: Adds in-depth operator training, equipment inspections, and integration with continuous improvement processes.