Course Description

This 1-day Failure Mode and Effects Analysis (FMEA) with VDA course equips participants with the knowledge and skills to identify, evaluate, and mitigate potential failures in products and processes using the latest AIAG & VDA FMEA Handbook methodology. FMEA is a structured, proactive tool for assessing risks and prioritizing actions to prevent quality and reliability issues.

Through interactive discussions, practical exercises, and real-world case studies, participants will learn the 7-step FMEA process, how to rate Severity, Occurrence, and Detection, and how to calculate and use the Action Priority (AP) rating. This training emphasizes the financial benefits of FMEA, including reduced scrap and rework, minimized warranty claims, improved product reliability, and enhanced customer satisfaction.

Course Objectives

Understand FMEA Principles:

– Define FMEA and its role in risk management and quality improvement.

– Explain the AIAG & VDA FMEA 7-step approach.

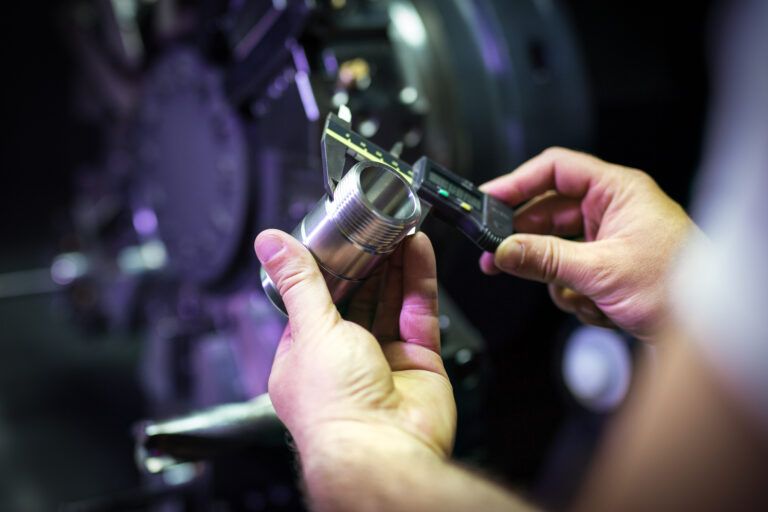

Apply the FMEA Methodology:

– Develop Structure Analysis, Function Analysis, and Failure Analysis.

– Rate Severity, Occurrence, and Detection effectively.

Prioritize and Mitigate Risks:

– Use the Action Priority (AP) system to determine corrective actions.

– Integrate preventive and detection controls into processes.

Link FMEA to Financial Performance:

– Quantify savings from reducing product failures, scrap, and warranty claims.

– Demonstrate ROI from proactive risk management.

Integrate FMEA into Continuous Improvement:

– Use FMEA results to strengthen process capability.

– Align FMEA with customer-specific and industry standards.

Training Format

Day 1: Introduction to AIAG & VDA FMEA principles, step-by-step application of the 7-step process, hands-on FMEA exercises, and linking FMEA results to financial and operational performance improvements.