Course Description

This flexible-duration Total Productive Maintenance (TPM) course (1, 2, or 3 days) provides participants with the knowledge and skills to implement a proactive maintenance strategy that maximizes equipment effectiveness, minimizes downtime, and extends asset life. TPM engages all employees, from operators to management, in maintaining and improving equipment performance.

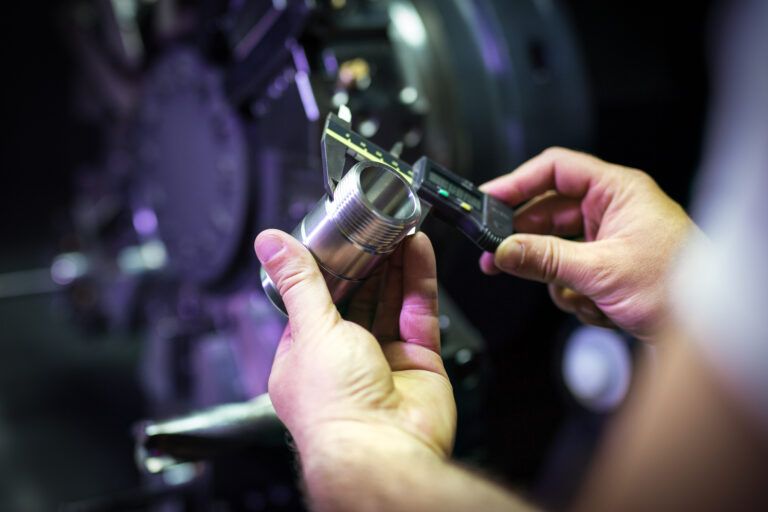

Through interactive workshops, hands-on activities, and real-world case studies, participants will learn the eight pillars of TPM, how to identify and eliminate the root causes of equipment loss, and how to measure and improve Overall Equipment Effectiveness (OEE). The course emphasizes the financial benefits of TPM, including reduced maintenance costs, increased production capacity without capital investment, fewer breakdowns, and improved product quality.

Course Objectives

Understand TPM Principles:

– Define Total Productive Maintenance and its role in Lean manufacturing.

– Explain the eight pillars of TPM and their benefits.

Measure and Improve Equipment Effectiveness:

– Calculate Overall Equipment Effectiveness (OEE).

– Identify and address the six big losses impacting equipment performance.

Engage the Workforce in Maintenance:

– Empower operators to take an active role in basic equipment care.

– Build cross-functional collaboration for maintenance improvements.

Link TPM to Financial Performance:

– Quantify cost savings from reduced downtime, fewer breakdowns, and increased throughput.

– Connect TPM results to ROI and long-term asset value.

Sustain TPM Improvements:

– Develop preventive and predictive maintenance schedules.

– Implement visual controls and audits to maintain performance gains.

Training Format Options

– 1-Day: Introduction to TPM principles, OEE measurement, and quick-start maintenance improvement activities.

– 2-Day: Adds in-depth analysis of equipment losses, team-based problem-solving, and maintenance planning.